In my 15 years of packaging machine manufacturing, I've seen countless customers struggle with hard-to-open packages. Their customers get frustrated, and product satisfaction drops.

A tear notch is a small v-shaped or curved cut on the edge of flexible packaging that creates an easy opening point. It helps customers open packages without scissors and improves their experience with your product.

I've helped hundreds of businesses implement tear notches in their packaging. Let me show you everything you need to know about this simple yet powerful feature.

What is a Tear Notch?

Last week, a client called me about customer complaints regarding difficult-to-open packages. Their sales were dropping, and they needed a solution fast.

A tear notch is a strategically placed notch or slit in the packaging material that creates a controlled starting point for tearing. It's like having a built-in scissors that guides the tear in the right direction.

Understanding Tear Notch Designs

When I design packaging solutions, I consider three main types of tear notches:

V-Shaped Notch

The most common design I recommend for most applications. It provides:

- Clear visual indication of where to tear

- Precise tear initiation point

- Consistent tearing direction

Curved Notch

I often suggest this for premium products because:

- It looks more sophisticated

- Provides a smoother tearing experience

- Works well with thicker materials

Euro Notch

This is my go-to solution for larger packages:

- Deeper cut for easier gripping

- Works well with heavy-duty materials

- Perfect for industrial applications

Tear Notch Positioning

Through years of testing at Packerio, I've found these optimal positions:

| Position | Best For | Benefits |

|---|---|---|

| Corner | Small pouches | Easy to locate, natural tearing motion |

| Side | Stand-up pouches | Better stability, controlled opening |

| Top | Pillow bags | Prevents product spillage |

How to Make a Tear Notch?

I remember when a small snack company came to me with high product returns due to packaging issues. After implementing our tear notch solution, their customer complaints dropped by 80%.

Making a tear notch requires precise machinery and careful consideration of material properties. The process involves using specialized cutting tools that create clean, precise notches without compromising package integrity.

Manufacturing Process

In my factory, we follow a systematic approach to tear notch creation:

Tool Selection

The right tool makes all the difference:

- Tungsten carbide blades for clean cuts

- Custom-shaped dies for consistent results

- Automated pressure control systems

Quality Control Measures

We've developed strict quality standards:

- Regular blade inspection and replacement

- 100% visual inspection of notches

- Pull-force testing on sample packages

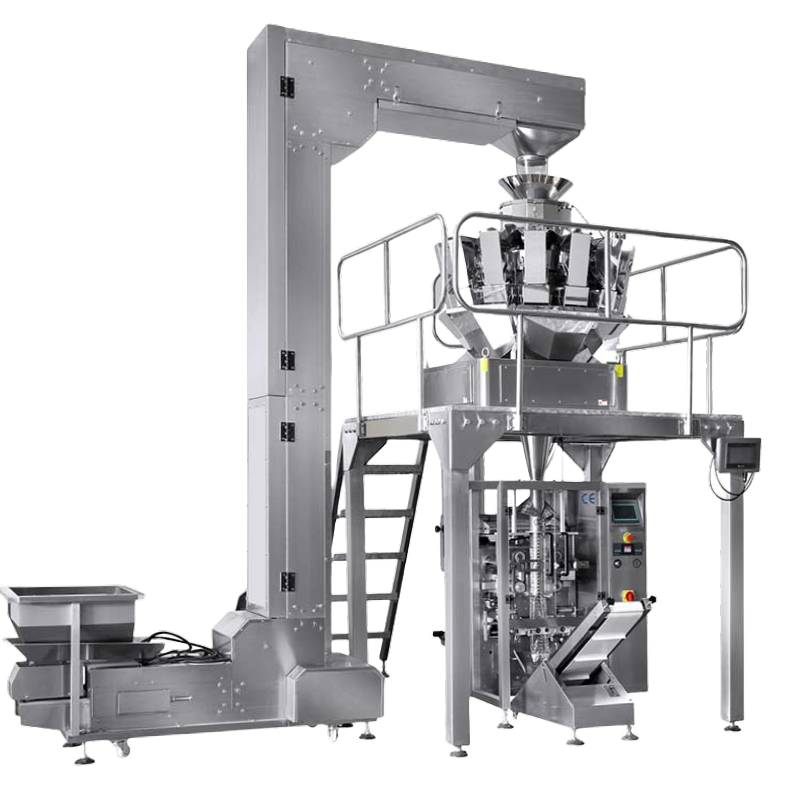

Integration with Packaging Lines

Our machines seamlessly integrate tear notch creation:

- Synchronized with filling operations

- Real-time quality monitoring

- Automatic rejection of defective notches

What Material is Used for Pouch Packaging?

During a recent consultation, a client was confused about which material would work best with tear notches. This is a critical decision that affects both functionality and cost.

The most common materials for pouch packaging are BOPP, PET, and PE films, often combined in multi-layer structures. The choice depends on your product's requirements for barrier properties, strength, and tear resistance.

Material Selection Guide

Based on my experience with thousands of packaging projects:

Basic Film Types

I typically recommend these materials:

| Material | Strength | Cost | Best For |

|---|---|---|---|

| BOPP | High | Medium | Dry goods |

| PET | Very High | High | Premium products |

| PE | Medium | Low | General purpose |

Multi-layer Structures

For optimal performance, we often use combinations:

- BOPP/PE for standard applications

- PET/AL/PE for high barrier needs

- NY/PE for tough products

Special Considerations

Some factors I always discuss with clients:

- Product shelf life requirements

- Environmental conditions

- Cost constraints

- Sustainability goals

Conclusion

After implementing thousands of tear notch solutions, I can confidently say it's one of the most cost-effective ways to improve package usability. Choose the right design and material, and your customers will thank you.